Maintaining and extending the lifespan of farm equipment is crucial for ensuring continuous productivity and reducing operational costs. By implementing effective maintenance strategies, farmers can optimize equipment performance, minimize downtime, and enhance overall profitability. This guide outlines best practices for extending the life of your farm equipment, focusing on regular maintenance, proper storage, and quality parts.

Regular Maintenance and Inspections

Regular maintenance is the cornerstone of extending equipment lifespan. It involves a combination of routine checks and scheduled servicing:

-

Daily and Weekly Checks: Perform daily visual inspections and weekly checks of fluids, tires, belts, and hoses to identify potential issues early.

-

Monthly Maintenance: Regularly inspect lubrication points, hydraulics, and batteries to ensure optimal performance.

-

Seasonal Inspections: Conduct thorough inspections before heavy-use seasons to ensure equipment is in peak condition.

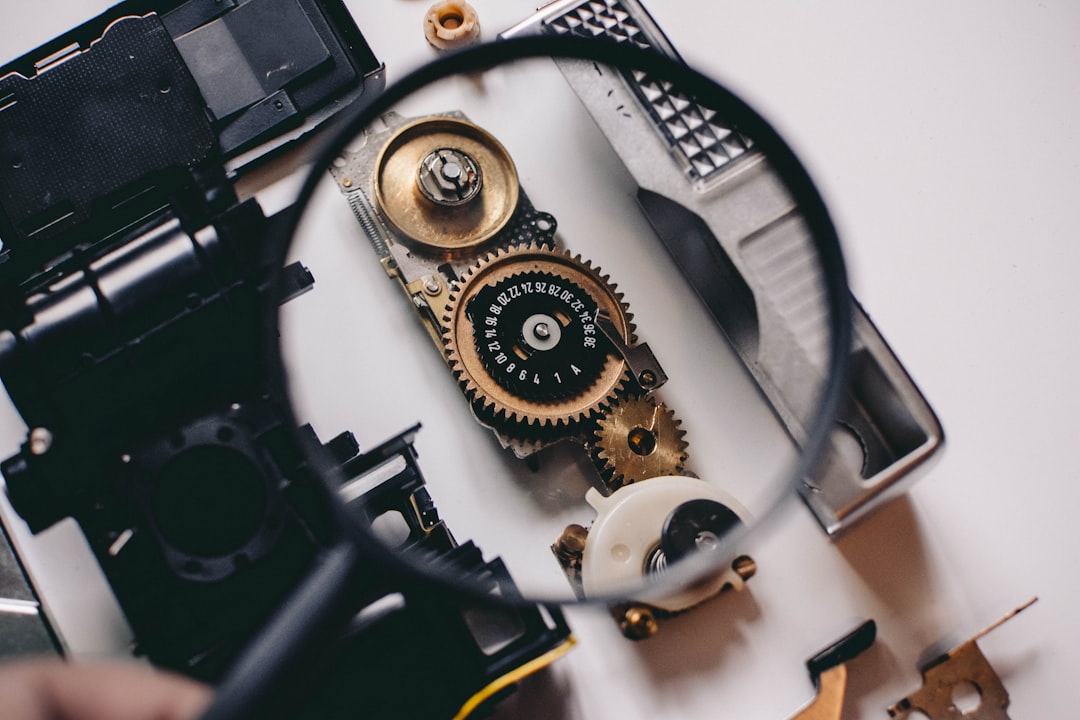

Proper Cleaning and Lubrication

Cleaning and lubrication are essential for preventing wear and tear:

-

Cleaning After Use: Remove dirt and debris from equipment after each use to prevent corrosion and maintain functionality.

-

Lubrication: Apply high-quality lubricants to moving parts to reduce friction and wear.

Correct Storage Practices

Proper storage protects equipment from environmental damage:

-

Indoor Storage: Store equipment in a dry, covered area to prevent rust and corrosion.

-

Outdoor Storage: If indoor storage isn't possible, use waterproof covers to shield equipment from rain and sunlight.

Use of Quality Parts and Fluids

Using high-quality parts and fluids ensures optimal performance and longevity:

-

Original Equipment Manufacturer (OEM) Parts: Stick to OEM parts for replacements to maintain compatibility and performance.

-

Premium Fluids: Use high-grade oils and lubricants that last longer and provide better protection.

Operator Training and Best Practices

Proper operator training reduces the risk of equipment damage:

-

Comprehensive Training Programs: Educate operators on correct usage, maintenance, and troubleshooting techniques.

-

Safe Operation Practices: Ensure operators understand safety protocols and follow best practices to prevent accidents and equipment damage.

Record Keeping and Maintenance Scheduling

Maintaining detailed records helps track maintenance activities and plan future servicing:

-

Service Logs: Keep a log of all maintenance activities, including dates, parts replaced, and personnel involved.

-

Scheduled Maintenance: Use manufacturer-provided schedules to ensure timely maintenance and prevent unexpected failures.

Conclusion

Extending the lifespan of farm equipment requires a proactive approach that combines regular maintenance, proper storage, quality parts, and operator training. By implementing these best practices, farmers can significantly reduce repair costs, minimize downtime, and enhance overall equipment performance. Whether you're managing a small farm or a large-scale operation, these strategies will help ensure your equipment remains in top condition, supporting long-term productivity and profitability in agriculture.

Citations:

- https://www.fmworldagri.com/farm-equipment-maintenance-guide.html

- https://www.farmbrite.com/post/guide-to-farm-equipment-care-and-maintenance

- https://sipiesmobilewash.com/6-preventive-maintenance-of-farm-tools-and-equipment/

- https://www.morningagclips.com/best-practices-for-extending-the-life-of-your-farm-machinery/

- https://eworkorders.com/cmms-industry-articles-eworkorders/farm-maintenance-tips/

- https://www.cenex.com/en/expert-advice-and-insights/5-preventative-maintenance-tips-for-farming-equipment

- https://www.indostarcapital.com/cost-effective-ways-to-maintain-and-extend-the-life-of-farm-equipment/

- https://metrobi.com/blog/essential-farm-equipment-maintenance-tips-for-2025/

- https://every-tractor.jp/2023/11/01/tips-to-make-your-agricultural-machinery-last-longer/

- https://www.machinerylubrication.com/Read/32190/proactively-maintaining-your-agricultural-equipment

Comments

No comments yet. Be the first to comment!

You must be logged in to comment. Login